Lead edge paper feeding unit

1.The designed lead edge paper feeding technology has solved the problem of paper scratching for laminated,

varnished coated papers currently on the market. (This part includes applications such as a professional pap loosening roller structure, a special grid plate lifting action, and an automatic air suction and release device.)

2.The use of the dual - servo electrical system separates the paper feeding and paper transporting operations.

They are both interconnected and have their own division of labor.

3.A large capacity blower with frequency conversion adjustment can control the air volume at any time, providing appropriate paper feeding pressure for paper transportation, once again providing favorable conditions for reducing paper scratching. Moreover, it can accurately transport papers with large deformation and much warping, reducing the limitations of die cutting machines on paper varieties.

4. The durable conveying rubber roller adopts a detachable structure, which is convenient for use and easy to replace, reducing downtime. Also, only the worn - out part can be replaced, avoiding the trouble of replacing the entire shaft and reducing the subsequent maintenance cost of the machine.

5. High quality conveyor belts provide a smooth supply for the machine all the time. They reduce the relative friction

of the paper, prolong the service life, and at the same time, the designed detachable structure provides convenient conditions for later maintenance, which is more convenient and simpler compared with the disassembly and replacement of the entire shaft.

6.The side beating paper blocking device can be adjusted simultaneously or individually, which is accurate, time

saving, and labor - saving for adjusting the position of the paper stack, improving the efficiency of machine adjustment and paper replacement.

Positioning and transport unit

1.High power servo drive for paper transfer and with a unique curve trajectory, to ensure that the paper in place and accurate.

2.Phase adjustment and PLC control precision.

3. There are one sets positioning push gauge on both sides, it ensure the positioning accuracy of side paper.

4.Front and side gauge designed with wide, it makes high precision on the framed paper.

5.Front gauge with vernier device of gripper, simply turn the hand-wheel to align the gauge.

6.Unique design of upper and lower front gauge matching gripper mechanism ensure that the warped paper can be transferred smoothly and ensure the die cutting precision.

7.The gripper bar is made of aluminum magnesium alloy, with high strength and no deformation. All screws and nuts of the gripper bar are made of standard anti-loosening screws and nuts.

8.Imported transmission chain, high strength oil-containing nylon chain guide board and oil drop type automatic lubrication device, low noise at high speed.

Main drive unit

1.The main driving system adopts worm wheel and worm gear pair and special crank shaft linkage mechanism connected by bearing shell. Low noise, high pressure and accuracy, long service life Worm wear-resistant material selection of quality copper alloy by precision machining.

2.High quality nodular cast iron is used in main part and die cutting platform, it has the characteristics of wear resistance and low deformation coefficient.

3.The main drive lubrication: high pressure gear pump lubricates uninterruptedly .The protect device for abnormal and filter is installed in the oil road, ensure the machine internal same as new machine after many years.

4.The big turning pneumatic clutch responds the speed quickly, the dint is big, and usually need not maintained, making started, nasty stopped, ordered to move, act accurately, and no maintenance, with long serve life.

Die-cutting unit

1.The die cut plate fastened with four claw nut , ensure the large size paper die always smooth, and with pneumatic locking device,when change the plate more effectively .

2.The steel plate is made of hardened manganese alloy steel material, life is very long. The plate pneumatic suspension device, easy handling.

3.Die-cutting pressure electric regulation, more convenient and quick.

4. 350 T die cutting pressure , no matter cardboard ,corrugated paper , thick paper all easily die cut .

5.Die-cut paper or wast paper fall and other abnormal automatic control, realize the humanization and automation of mechanical operation.

6. Lower die cutting table with high precision of turbine, crank and toggle link connection type.

7.Upper die cutting table with stationary and high precision.

8. Equipped with Multi-chip CAM intermittent drive mechanism.

9. Equipped with high precision imported gripper bars.(Imported original IWIS chain)

10. 5 high precision imported gripper bars, each gripper bars has 8 grippers(imported spring sheet) and matching pillows.

11.Reservation position of gripper bar make sure the step spacing is correct and consistent.

12.Paper inlet and outlet are equipped with sensors which can detect the paper position and paper size.

13.Center line system in plate, it makes the plate changing quick and easy.

14.Equipped with electronic fault display and speed display device.

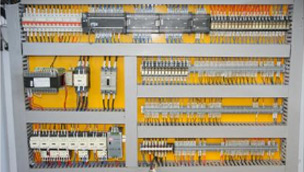

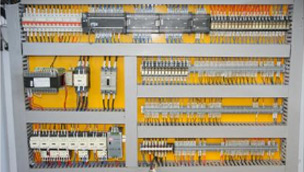

Electrical control system

1.The machine adopts Japan IDED company overall solution, with central high speed PLC control, touch screen parameter setting and real-time communication monitoring, stable and easy maintenance.

2.With the function of troubleshooting solution prompt.

3.Equipped with CE standard safety protection device and warning device, to ensure the safety of operator and machine.

4.The main motor adopts high protection grade motor and imported frequency converter, the power is never interrupted.

Electric - driven secondary paper collecting and high - platform stacking paper collecting part:

1. This machine is equipped with an electric - driven secondary paper collecting device, which enables non - stop paper feeding and collecting and improves production efficiency. The secondary paper - collecting adopts the curtain style to effectively carry the overall area of all kinds of die - cut papers, avoid the adverse consequence that papers cannot be smoothly received due to improper gaps in the paper collecting structure, and ensure the neatness of the paper stack. It is also applicable to some soft and thin papers in particular.

2. The stacking paper collecting method can meet customers' different requirements for paper stacks, so as to be more flexibly mastered.