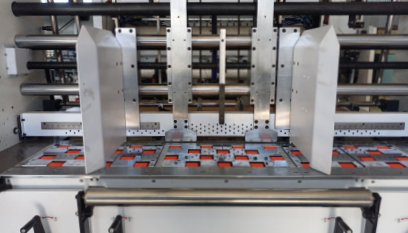

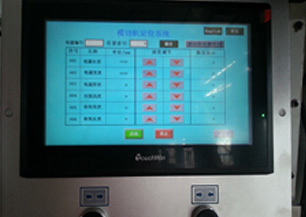

C165 full-automatic die-cutting&creasing with stripping station machine adopted leading edge paper feeding, high pressure fan frequency control air volume, suitable for most paper. The digital management of "one-key machine adjustment" completely solves the difficult problems of paper adjustment time-consuming, laborious and difficult to master. Just enter the parameters of each order paper, and after one-key start, the eight adjustment steps can be automatically adjusted in place. Greatly improve work efficiency. At the same time, the high-capacity storage space can record 490 orders at a time. When the order is used again, as long as the record is recalled, it can be directly adjusted in place. It saves time to adjust again. In this way, whether it is a long order or a short order, the adjustment can be easily handled.

13315592123

13315592123

中文

中文

Unified national service hotline

13315592123

Unified national service hotline

13315592123

13315592123

13315592123