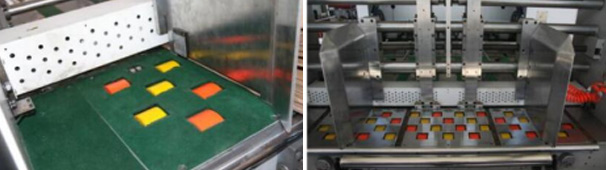

C150B machine is a special equipment for die-cutting of high-end color boxes , developed by our company in combination with the superior performance of similar products at home and abroad. This machine uses high-strength paper grippers. The advanced opening gripper mechanism can adapt to various types of cardboard and corrugated paper; the front and rear positioning and side positioning mechanisms ensure the accuracy of die-cutting paper. Equipped with high-precision intermittent mechanism; rapid-action pneumatic clutch and pneumatic lock plate. Using programmable controller and man-machine interface, display of the machine's working speed, number of processed sheets, and total running time; the machine's fault display makes troubleshooting operations very convenient. The inverter is used to control the main motor, stepless speed regulation, and stable operation. The machine is equipped with sensors and safety devices in many places to ensure the normal operation of the machine and personal safety. Die-cutting pressure can be adjusted separately , manual turning is convenient and labor-saving, and can die-cutting without bit mouth.

13315592123

13315592123

中文

中文

Unified national service hotline

13315592123

Unified national service hotline

13315592123

13315592123

13315592123