Lead edge feeding

The uniquely designed leading edge paper feeding technology device adopts a non-stop downward suction method, which overcomes the warpage of the cardboard caused by the difference in the number of grams of paper in the surface of the temperature and humidity, and makes the paper feeding more smoothly. The machine's unique servo paper feeding system improves the accuracy of the paper in place, and the unique motion control program completely eliminates the phenomenon of drawing and scratching. The side flapper device keeps the correct position of the paper stack when feeding the paper. Only the length of the paper is input when feeding the paper, and the feeding wheel can completely send the paper out.

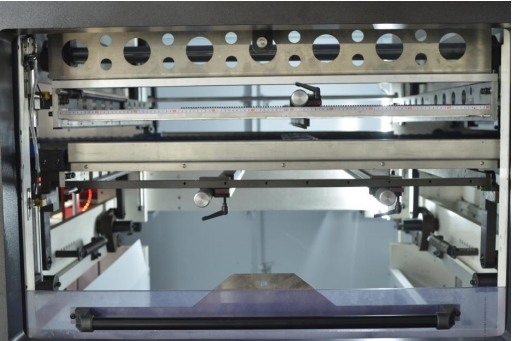

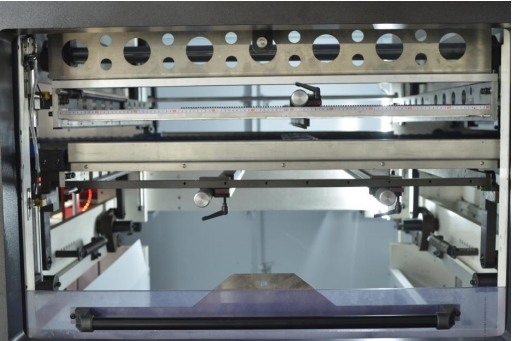

Paper positioning and conveying section

1. The paper feeding and conveying adopts high-power servo drive, and is equipped with a unique curved motion track to ensure accurate paper in place.

2. The PLC control of phase adjustment is more precise.

3. Side positioning push gauge, one set on each side. There is a large choice of reference surface to ensure the positioning accuracy of the paper side feeding.

4. The front gauge and the side gauge adopt a wide design, and die-cut with the same high precision as the laminated paper.

5. The front gauge has a left and right gripper fine adjustment device, and it can be aligned by simply turning the hand wheel.

6. The unique upper and lower front gauges cooperate with the gripper mechanism to ensure that the warped paper can be transferred smoothly and die-cutting accuracy.

7. The gripper bar adopts aluminum-magnesium alloy profile, which has high strength and does not deform. All screws and nuts of the gripper bar adopt anti-loosing standard screws and nuts.

8. Imported conveyor chain, high-strength oil-containing nylon chain guide plate and drip-type automatic lubrication device, high speed and low noise.

Main drive

The main drive adopts a worm gear pair and a specially designed crankshaft connecting rod mechanism, which has the characteristics of low noise, high pressure, high precision and long mechanical life. The worm wheel, worm and crankshaft are all processed by CNC grinding. The combined transmission of ternary gears is durable.The main machine body, upper and lower die-cutting platforms are all made of high-grade ductile iron materials and aging treatment. It has the characteristics of wear resistance, large mechanical flat pressure, and low deformation coefficient.The main drive lubrication adopts oil-immersion type and imported high-pressure gear pump uninterrupted lubrication method. The oil circuit is equipped with an organic oil filtering and cleaning device and an abnormal oil pressure protection device to ensure that the inside of the machine is always new. The clutch adopts a large-torque pneumatic clutch, which has fast response speed and large torque, and the actions such as start, emergency stop, and inch move are accurate, and it does not require maintenance and has a long life.

Die Cutting Department

1. The die-cutting plate is fastened with four-claw nuts to ensure that the large-format die-cutting plate is always flat, and equipped with a pneumatic plate locking device, which effectively reduces the preparation time for plate change.

2. The steel plate adopts the quenched manganese alloy steel material, which has an extremely long life. The steel plate pneumatic suspension device can be easily loaded and unloaded.

3. Electric adjustment and adjustment of die cutting pressure are more convenient and quick.

4. The equipment can easily die-cut corrugated paper and thick board paper with 350 tons pressure.

5. Abnormal automatic control of loose plates, paper falling, etc., to realize humanized automation of mechanical operation.

6. Worm gear crank shaft type high precision plane die-cutting table.

7. Fixed high-precision flat die cutting upper worktable.

8. The latest technology multi-piece cam intermittent transmission mechanism.

9. Imported high-precision gripper gear transmission chain.

10. The machine has 7 gripper bars, each with8 (imported spring steel sheets) grippers and matching griper pillows.

11. Pre-positioning of teeth row to ensure correct and consistent step positioning.

12. The paper inlet and the paper outlet are equipped with electric eyes, and the paper is in place and the paper width detection response is quick.

13. The template is installed with a central positioning system for quick and easy plate change.

14. Electronic fault display and speed display.

Paper stripping Department

The upper and lower two frame quick clamping devices and the use of a central positioning system (interchangeable and compatible international standard molds) are easy to change the plate. The upper frame is separated by the cylinder lifting control. The bottom stripping template fixing machine adopts a central positioning system, which is easy to operate. The front stripping function adopts the central positioning system to remove the paper edge in the machine at one time.

Automatic Paper Collection department

1. The linear bearing is adopted for the paper receiving and aligning, the structure is simple, and the paper receiving is neat.

2. Automatic paper stack lifting table and counting function, accurate collection of papers.

3. Non-stop delivery of paper ensures that the whole machine does not stop running.

4. The output adopts a drive roller (the belt can be selected by the customer).

It is fast and convenient to take in the paper. It can realize the high and low position interchange, and ensure that the printing is free from scratches and patterns.

5. Non-stop counting delivery and stack delivery automatically switch.

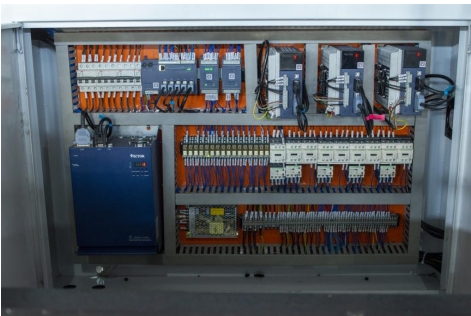

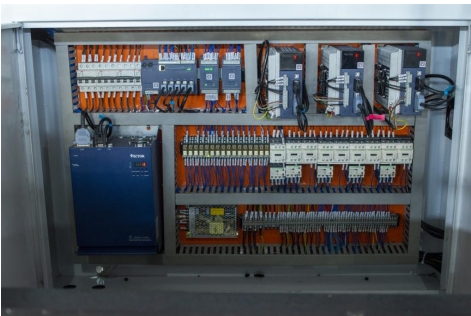

Electrical Control Department

1. The whole machine adopts the overall solution of Japanese IDED, central high-speed PLC control, touch screen parameter setting and real-time communication monitoring, stable and convenient for maintenance.

2. Prompt for Troubleshooting Tips.

3. CE standard safety protection device and warning device to ensure the safety of man and machine.

4. The main motor adopts high protection grade motor and imported frequency converter, and the power is never interrupted.

13315592123

13315592123

中文

中文

Unified national service hotline

13315592123

Unified national service hotline

13315592123

13315592123

13315592123