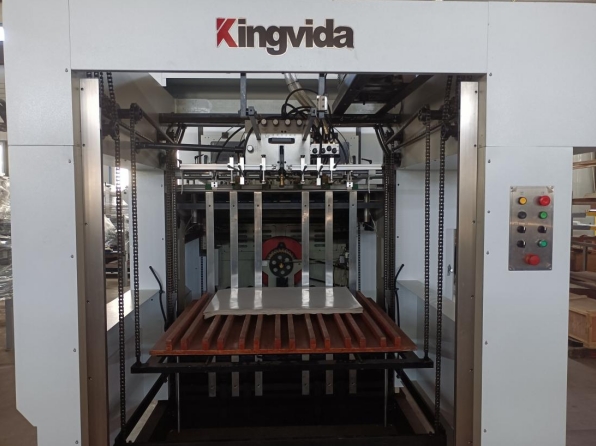

The MY1300 fully - automatic die - cutting and creasing machine is a special - purpose equipment developed by our company in combination with similar products at home and abroad, which is suitable for high - grade color boxes and color box die - cutting. This machine uses a paper - gripping mechanism to adapt to all types of cardboard and thin corrugated paper. The front - rear positioning and side - positioning mechanisms ensure the die - cutting accuracy of the paper; it has a precision intermittent mechanism; pneumatic clutch for movement speed, pneumatic plate - locking; it uses a programmable controller and a human - machine interface, and digitally displays the working speed, number of processed sheets, and total running time of the machine; the fault display of the machine makes fault - elimination operations convenient. The application of a frequency converter to control the main motor enables stepless speed regulation and stable operation; sensors and safety devices are installed in multiple parts of this machine to ensure the normal operation of the machine and personal safety. The die - cutting pressure can be adjusted separately at the front and rear, and the manual turning of the handwheel is convenient and labor - saving. At the same time, die - cutting without gripper margins can also be carried out; an auxiliary paper - feeding device is added to the paper - feeding part, an auxiliary paper - collecting device is added to the paper - collecting part, and the whole stack of die - cut paper is transferred out, enabling non - stop paper - feeding and paper - collecting.

Performance characteristics

1. The paper feeding and die cutting size is the largest 1300*1025 among the same model of machines in the world. It can realize bite-free die cutting of many products.

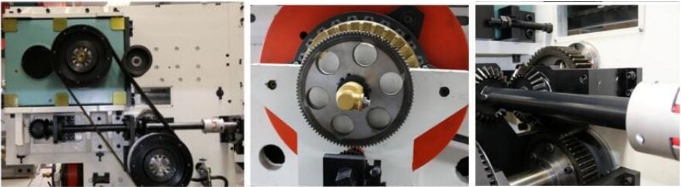

2. The transmission mechanism adopts non-chain and transmission shaft transmission. Low noise.

3. The super-large intermittent mechanism is 320 intermittent , the machine is more stable, and the machine speed can reach 6500 sheets/hour.

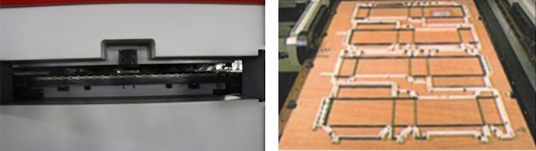

4. The main gripper bar chain adopts imported chain, which is pneumatically tightened, which increases the service life of the gripper bar chain.

5. The heavy-duty feeder with 4 suctions and 5 feeds can easily feed tile paper within 8mm.

6. Wide application range: cardboard and corrugation within 8mm.

7. Die-cutting accuracy of cardboard +-0.1mm (cut medicine box can guarantee accuracy)

8. The machine adopts a fully automatic oil supply system to ensure proper lubrication of the machine.

9. The steel plate frame is made of 65 #manganese steel plate, the quenching hardness is HRC 55-60 degrees. The same hardness as the knife line, more wear-resistant.

13315592123

13315592123

中文

中文

Unified national service hotline

13315592123

Unified national service hotline

13315592123

13315592123

13315592123