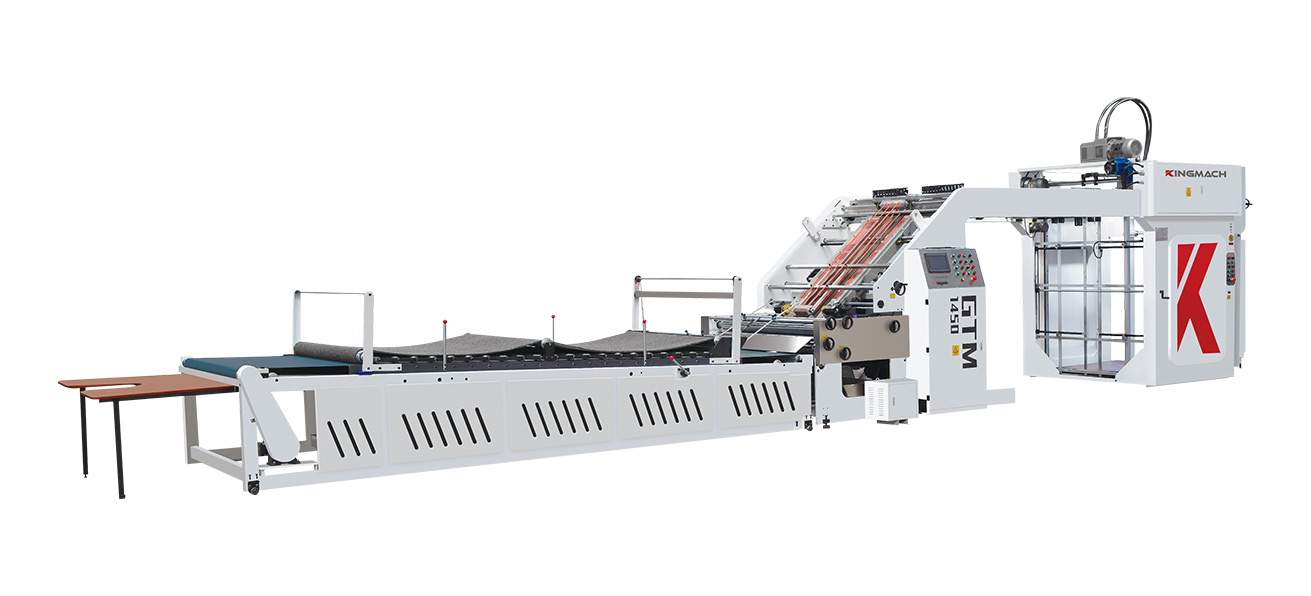

GTM1450

| Model | GTM1450 |

| Max. Paper Size | 1450X1450mm |

| Min.paper Size | 420X350mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | A、B、C、D、E、F 型瓦楞纸板 厚度≤ 10mm |

| Max.Speed | 160m/min |

| Lamindin Precision | ±1mm |

| Total Power | 31KW |

| Weight | 7500Kg |

| Overall Dimension | 13.5X2.3X 2.5M |

GTM1650

| Model | GTM1650 |

| Max. Paper Size | 1650X1450mm |

| Min.paper Size | 420X350mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | A、B、C、D、E、F 型瓦楞纸板 厚度≤ 10mm |

| Max.Speed | 160m/min |

| Lamindin Precision | ±1mm |

| Total Power | 33KW |

| Weight | 8000Kg |

| Overall Dimension | 14X2.5X2.5M |

GTM1900

| Model | GTM1900 |

| Max. Paper Size | 1900X1450mm |

| Min.paper Size | 420X350mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | A、B、C、D、E、F 型瓦楞纸板 厚度≤ 10mm |

| Max.Speed | 160m/min |

| Lamindin Precision | ±1mm |

| Total Power | 40KW |

| Weight | 9000Kg |

| Overall Dimension | 14X2.7X2.5M |

13315592123

13315592123

13315592123

13315592123