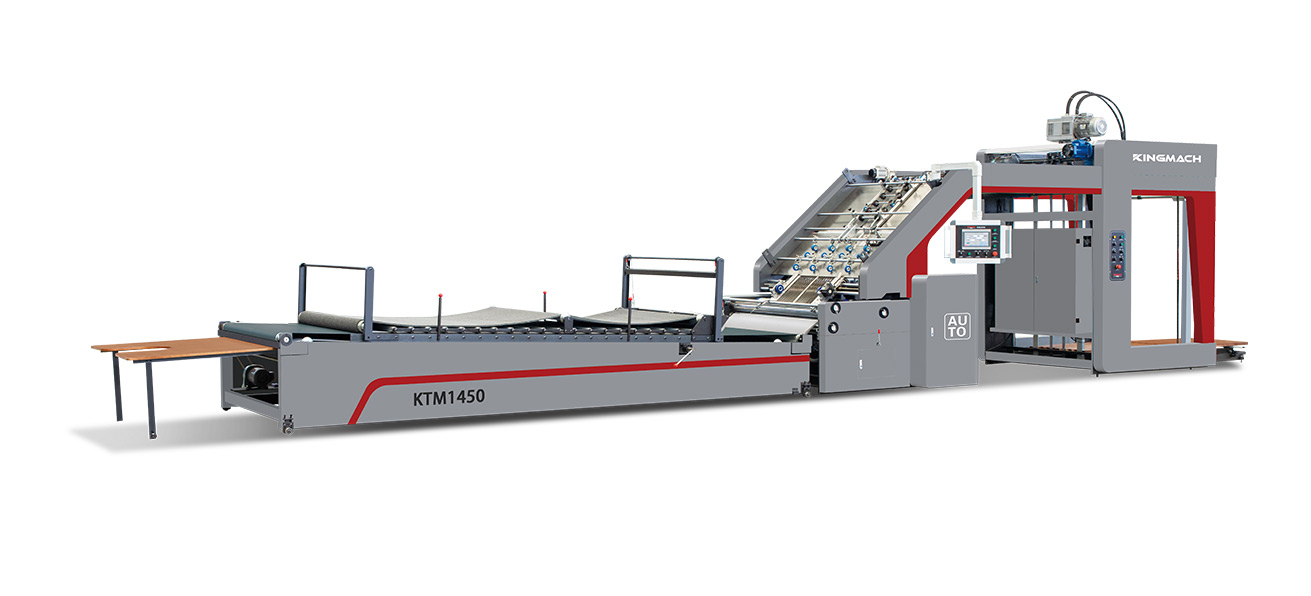

KTM1450

| Model | KTM1450 |

| Max. Paper Size | 1450X1300mm |

| Min.paper Size | 400x350mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | A、B、C、D、E、F型瓦楞纸板 厚度≤10mm |

| Max.Speed | 140m/min |

| Lamindin Precision | ±1mm |

| Total Power | 29KW |

| Weight | 6000kg |

| Overall Dimension | 12.5mx2.3mx2.5m |

KTM1650

| Model | KTM1650 |

| Max. Paper Size | 1650X1300mm |

| Min.paper Size | 400x350mm |

| Paper Thickness | 150-600g |

| Base Paper Thickness | A、B、C、D、E、F型瓦楞纸板 厚度≤10mm |

| Max.Speed | 140m/min |

| Lamindin Precision | ±1mm |

| Total Power | 30KW |

| Weight | 7000kg |

| Overall Dimension | 12.5mx2.5mx2.5m |

13315592123

13315592123

13315592123

13315592123