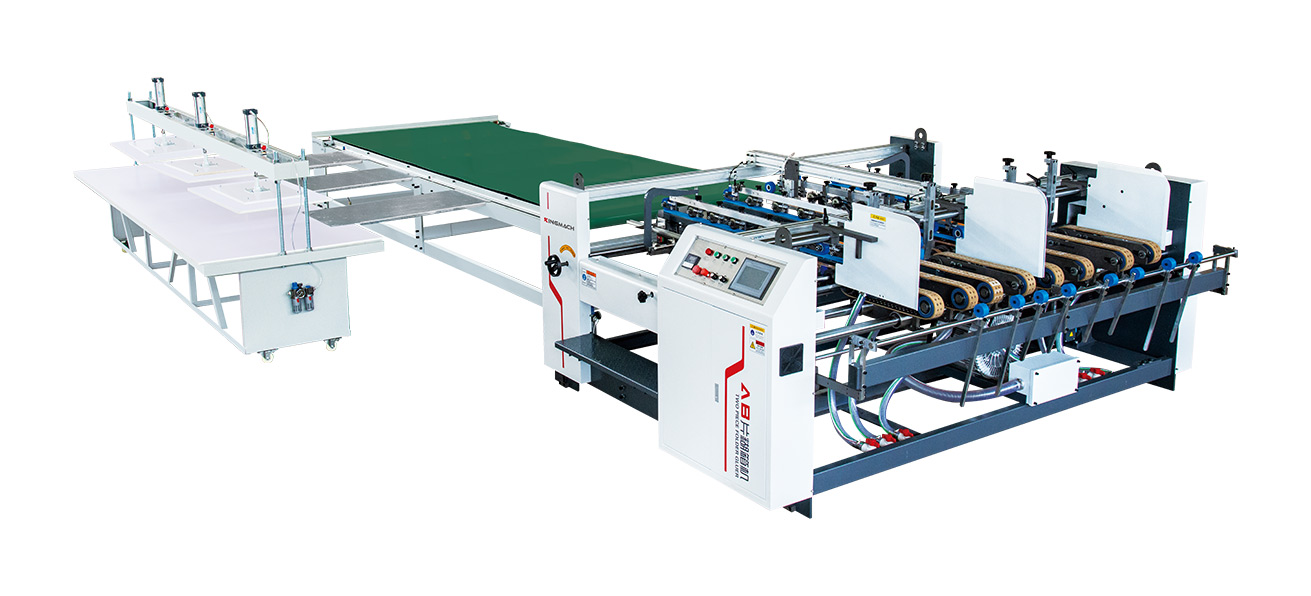

1. Paper collecting mechanism:Assembly line conveyor belt,small orders can be operated by one person, and large orders can be operated by multiple people at the same time, maximizing mechanical efficiency.

2. Paper feeding mechanism:The clutch is used to independently control the beef tendon color rubber punching belt with air suction, the paper feeding is stable and reliable, and the adjustment is convenient.

3. Positioning system: random adjustment of accuracy during operation to improve efficiency. Cylinder positioning system, accurate alignment, Imported cylinder maintenance-free.

4.4 independent upturned flush paper baffles, smooth output product without crimping, front and rear adjustable travel distance is long, can be applied to any special-shaped carton.

5. Gluing mechanism: Use cold and hot double glue unit to ensure the bonding stable and reliable , hot glue using aluminum glue box has fast thermal conductivity, cold glue using stainless steel glue box corrosion resistance. The adjustment is convenient to operate, and the gluing accuracy is high.

6. The computer display displays the speed and number of sheets, and the working mode of single and two pieces of paper is switched at will, just click the corresponding status button to complete. You can also check the cause of the fault on the display screen, indicating that the current action is not performed. Convenient for operators to troubleshoot faults.

JAB-C Characteristics:

1. Paper feeding mechanism:It adopts double servo independent control to ensure stable and reliable paper feeding, higher paper feeding accuracy and convenient adjustment.

2. Positioning system:Double servo motion control positioning system ensures more accurate carton alignment, (optional order memory and digital adjustment ) adjust faster.(*Special-shaped carton not applicable.)

3. 4 independent upturned flush paper baffles, smooth output product without crimping, front and rear adjustable travel distance is long, can be applied to any special-shaped carton.

4.Gluing mechanism: Use cold and hot double glue unit to ensure the bonding stable and reliable , hot glue using aluminum glue box has fast thermal conductivity, cold glue using stainless steel glue box corrosion resistance.

5. Paper collecting mechanism:Assembly line conveyor belt,small orders can be operated by one person, and large orders can be operated by multiple people at the same time, maximizing mechanical efficiency.

6. The computer display displays the speed and number of sheets, and the working mode of single and two pieces of paper is switched at will, just click the corresponding status button to complete. You can also check the cause of the fault on the display screen, indicating that the current action is not performed. Convenient for operators to troubleshoot faults.

The main differences between cylinder and servo models:

1. The cylinder type uses a clutch to feeding paper. The minimum paper 460*300mm ;server type uses vector

inverter+independent motor to feeding, reflect fast and higher stability. Minimum paper 500*150mm.

2. The cylinder type uses a high -speed cylinder to align paper, the maximum speed 3,000 boxes/hour; the servo type uses a servo motor &ball screw to control the paper . High reaction,maximum speed 3600 boxes/hour.

3. Cylinder -type the position of the middle glue box is relatively fixed with the paper pallets and the paper pressure plate. Only the cold glue box can be fine -tuned; the servo type intermediate glue box can be adjusted, the cold and hot glue box can be exchanged the position. It can also be adjusted, so that it is convenient for the adjustment of a double -glue product.

4. The cylinder -type the middle glue box is manually operated by the jaw clutch; the servo type is automatically operated by electromagnetic clutch. Servo type It is more convenient to adjust the single -piece carton.At the same time, the noise should be lower.

13315592123

13315592123

13315592123

13315592123