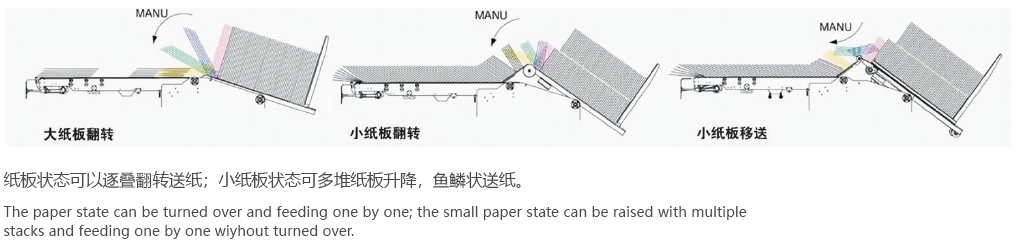

1. Reduce loss. The traditional manual paper feeding is easy to damage the cardboard, especially when handling the cardboard with a large area, both sides are lifted and the middle is sunken, which causes the cardboard to enter the printing machine poor printing and leaky white. A similar phenomenon can be avoided by using a paper feeding machine.

2. Improve efficiency and productivity. According to calculations, the speed of manual paper feeding is 80-150 sheets/minute, and the speed of feeding large cardboards is slower, which may only be 40-50 sheets/minute. If it is matched with a paper feeder, the production capacity will be increased by 30-60%. This not only improves feeding efficiency, but also helps equipment such as printing machine, flatbed die-cutting machine, and gluing machine at their best and run at optimum speeds.

3. Reduce labor intensity and reduce personnel turnover. As a labor-intensive enterprise, carton factory workers need to work 8-10 hours a day at high intensity, and the turnover rate is high. With the semi-automatic paper feeder, one person can carry the paper and one person can feed the paper.

4. Reducing losses, improving efficiency and productivity, and reducing labor intensity are the most obvious advantages of paper feeders, and for carton factories, the fundamental purpose of these advantages is to reduce costs. In the current market environment, the price of raw materials fluctuates greatly, and the low-price competition in the market is very common. The use of automated equipment to reduce production costs has become an industry consensus.

13315592123

13315592123

中文

中文

Unified national service hotline

13315592123

Unified national service hotline

13315592123

13315592123

13315592123